The most difficult parts of this project were troubleshooting five 3D printers, as well as working the kinks out using several different pieces of software. 3D printing seems to have made the process quite a bit easier and less tedious for Aztec Scenic Design.īutler told us that he believes that there are approximately 400 different 3D printed parts in this ceiling that they designed. It takes a lot of time making molds, and then building the customizations with plaster. All in all this was an extremely collaborative project that couldn’t have been done without the entire Aztec crew, along with our good friend James who helped model, print, and fabricate.”ģD Printed pieces laid out prior to being painted, and glazed.Īs anyone knows that has either helped build a custom ceiling, or had one done in their home, it can be extremely time consuming. The color choices were based on the clients current decor, and Ben and Gabriel made the final choices that you see. Then Marc took those sketches and turned them into 3D models with his own designs. Ben Cremer came up with the initial designs based on Arabian patterns. “He pioneered the idea of 3D printing these apliques instead of creating molds and using plaster to make the parts, and after months of trying to convince that 3D printing is the way of the future, Gabriel went for it! So once the idea was set that Aztec would expand and create a makerspace to facilitate our work, the ceiling design fit perfectly into what we could do.

“Marc Leonard has been working with Aztec Scenic Design for a long time now and recently he became obsessed with 3D printing, so he was trying to find a way to merge two of his favorite things,” he explained. We asked Austin Butler how this tremendous design idea came about:

Live home 3d pro ceilings install#

The final install of the ceiling took only 2 days. The design required about 6 spools of 3mm ABS filament and 3 spools of 1.75 PLA filament, which cost only a bit over $200. The printers used include a Tinkerine Ditto+ and several Prussa i3 8″ printers.

Live home 3d pro ceilings full#

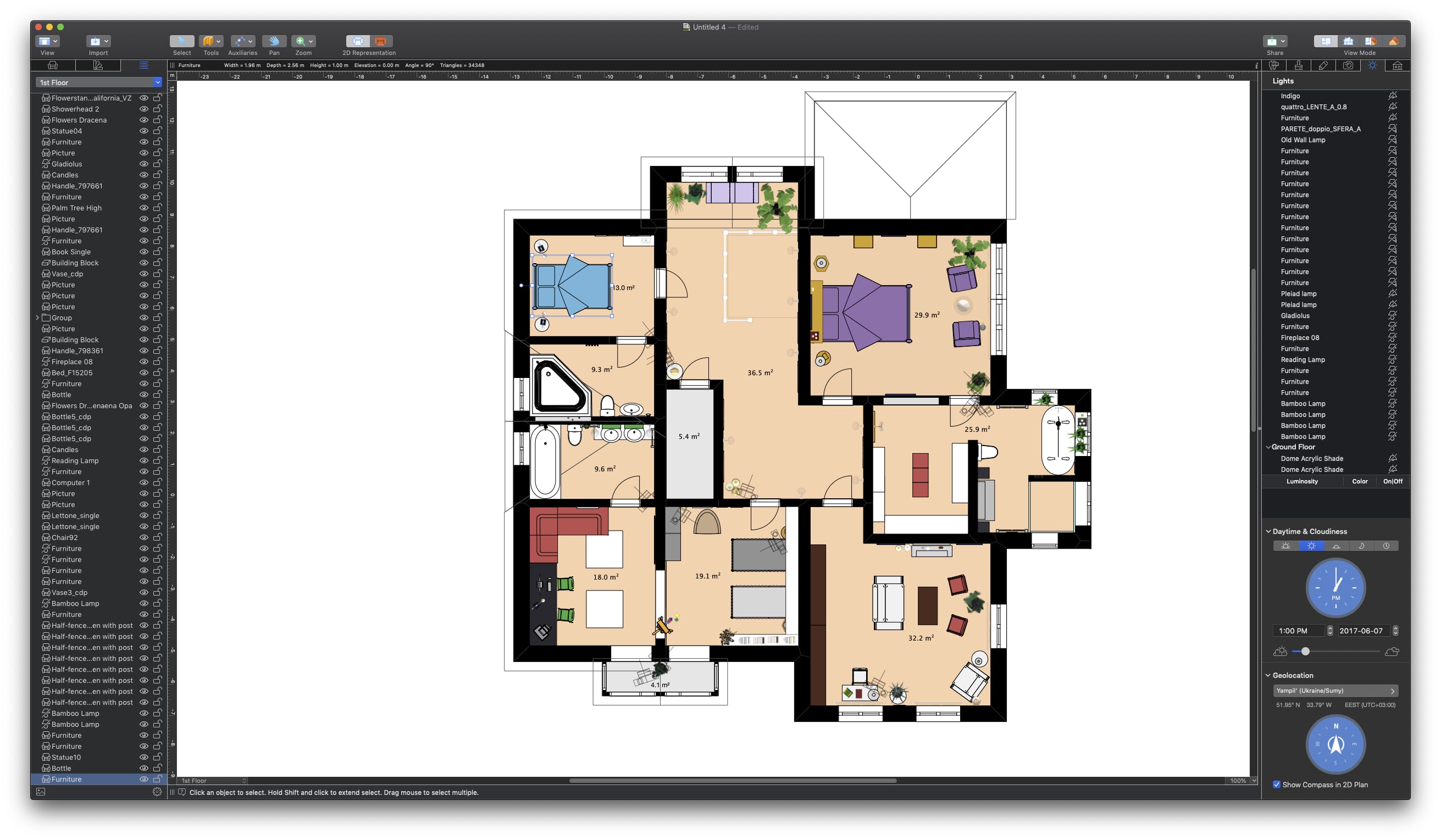

The overall size of this design is approximately 18 feet by 14 feet, and it took approximately 3 full weeks of printing on several different 3D printers. The parts were then painted with acrylic, and aged with oil stains, before getting touched up and finished with glaze. Then there is the moulding which was cut on a CNC router and then was gold-leafed. What you see in the photo below is 9 panels of wood that serve as the background, in which all parts are fixed to. We are continuing to work with this client and are currently designing another more complex ceiling for their theatre, along with other projects.” Once everything was printed the whole crew at Aztec (which includes the owner Gabriel Collazo, Marc Leonard, Benjamin Cremer, Janelle Lyons, Timothy Dameron) applied gold leaf, painted, aged, and installed the entire ceiling. Once we were up and running, I helped maintain the printers while they were printing and got the printed parts ready to be treated. Then Marc and I assembled three printers and created our own makerspace studio.

I came on board with Aztec Scenic Design about two months ago and started helping print the parts for this installation.

Then Marc Leonard modeled everything in 123D Design. “This project was based on drawings designed by Benjamin Cremer who works with us. “Aztec Scenic Design, recently created our own makerspace and is beginning to incorporate 3D printing into as many applications as we can allow,” Scenic Designer and Fabricator at Aztec, Austin K. They have taken it upon themselves to work with a client to design a very sophisticated custom ceiling, using 3D printing for the majority of the design. However, this appears to be changing, especially for one design firm, Aztec Scenic Design. Up until now, ceiling design and 3D printing were not typically thought of as being such a great combination. Detailed ceilings can cost upwards of $30,000+ to design and build. Ceiling design can be one of the more expensive aspects in a home.

0 kommentar(er)

0 kommentar(er)